Professional

Leading

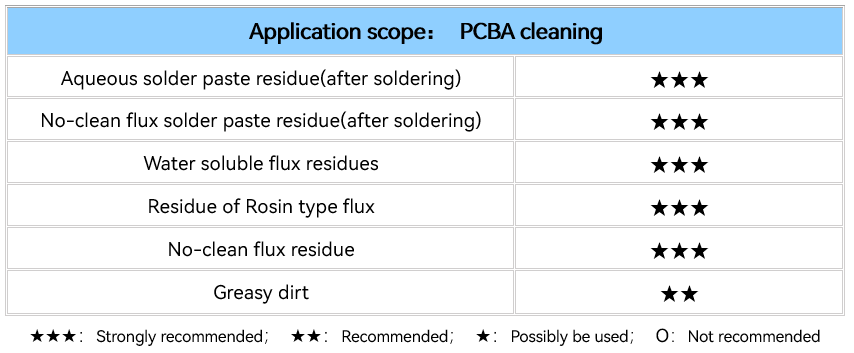

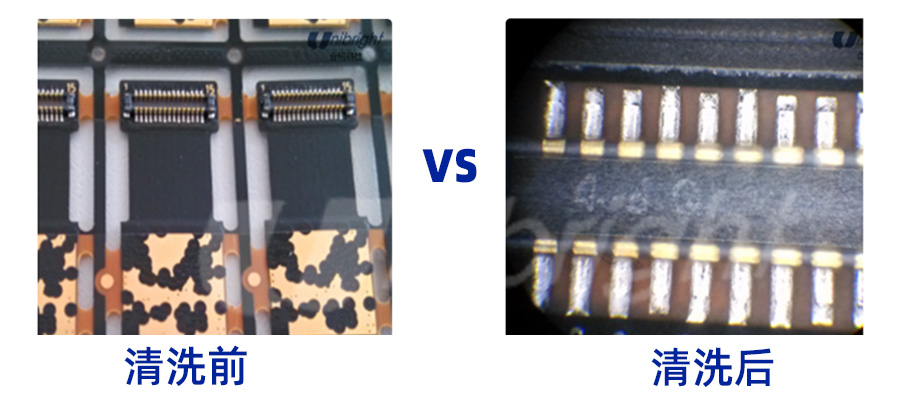

W3000 is mainly used to remove solder paste and flux residues after PCBA welding process. It also has a certain solubility in oil stains.

Ultrasonic cleaning process:

W3000 is used in the ultrasonic cleaning process, which can batch clean electronic assembly parts with complex structures. It can also achieve good cleaning results for low gap flux residues on the base. In the ultrasonic cleaning process, the parts to be cleaned are immersed in the cleaning tank, and the cavitation, acceleration, and direct inflow effects of ultrasound in the cleaning agent are combined with the super solubility of the cleaning agent to dissolve, disperse, emulsify, or peel off the dirt layer to achieve the cleaning purpose.

The application effects are listed in the following list.

![[x]](/en/template/default/picture/closeimgfz1.svg)